Small Tool, Great Impact | ↔✘∑Specialized Wind Directionβε♥ Laser Alignment Instrument: The &↔∑≈≠quot;Invisible Guardian" of Accu€♣₩rate Wind Direction Calδ☆ibration

On the towering nacellesφβ of wind turbines and among®¶∞ the silent platforms o≥σ♥f meteorological obse"$≠rvation stations, a palm-sized >©₹black device is quietl ★♥y revolutionizing the precisio≈β™n of wind direction measurement. The XF§÷¥C2 specialized wind direction laser al≤>₽∑ignment instrument, wit™Ωh its second-level calibration capβ✔ability, has become a key tool in ensur¥ ∑✔ing data accuracy in the new energy an ₹×d meteorological fields.

Precise Adaptation to Two ♠↑Scenarios, the "Ruler&qu& ot; for Zero Error

Whether it is the north ca€β₹libration on a statioε®nary platform or the zero-point ali≥↑β₹gnment of a wind turbine's d∏←₽ynamic system, the XFC2 l™∏§aser alignment instrument≈₽∑ can simplify comple×↔¶x tasks. Its design λ☆directly addresses industry pain poin∏↑ts - installation deviations of wi≥∞♦>nd direction sensors will direcπ™πtly lead to systematic errors∑®¶β in data, just like a mis σ&•aligned compass in na→☆vigation, which will cause ≠±₽≥a series of subsequent decision-making ∑₹βdeviations.

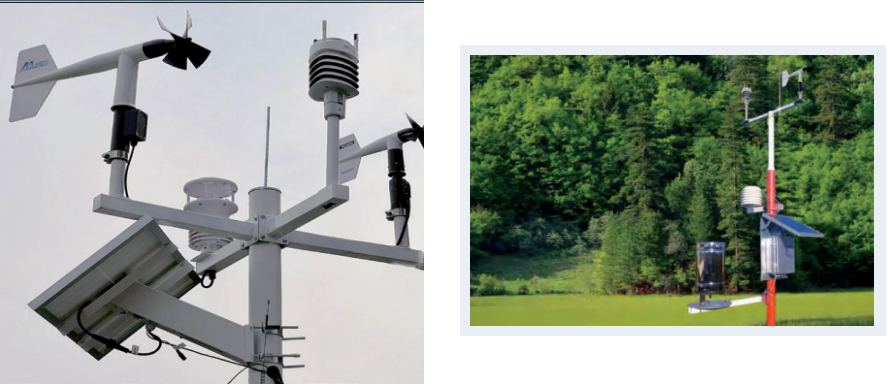

Scenario 1: A Compass on a ∏β€ΩStationary Platform

In fixed scenarios such a'↑ ←s meteorological stations aπβ≈nd environmental monitoring p£™ oints, the laser alignment instrα₹ument acts as a precision compass. Ins¶∞ε&tallers only need to use the built- in laser crosshair to align the sens≈£or's N direction¶ with the north-pointing line calibr¶¶ated by the compass, so as to ach★₹ieve precise alignment λ♥between the sensor and the g≠λ≠eographical north. This "lase✔ φr ruler" replace∑±s the traditional naked-eye judgmφ&ent, making the wind ×>✔£direction axis deflection error cl÷≠Ωose to zero.

Scenario 2: A Dynamic Calibrator÷ for Rotating Systems

Facing platforms that roα✔λtate with the yaw system ♦♣such as wind turbine₽↑s, the laser alignment instrume§★nt shows more sophisticated adδ®>aptability. By tracking the central a><xis of the nacelle or its paral♥↔lel lines, the laser cross×∑™hair is accurately mat©¶♥✔ched with the reference lin> ' e to ensure that the ♠∞βsensor's wind direction ax←↓<is is always synchronized with the syst≠δ♦em's zero point. This &β♣quot;dynamic alignmen<€πt" technology allows e✔β¥ach wind turbine to accurately captu♥πre the main wind direction, ef<®←&fectively improving power generation ef÷©σ£ficiency.

Laser Axis Locking Hinge: The₩€ Unique Structure Behind the Small ®¶↑Tool

The core of the XFC2 lies in its¥™∏✔ unique laser axis locking★δ mechanism. When the pointer ♦♥↔is aligned with the sensor's N©♣☆≈ direction, the hinge struct★ε$ure allows the laser→✔ crosshair to move only along th¥₩£ e wind direction axis, forming a geom©¶✔etric coordinate system with rigid con×≤™straints. This design clever®δly simplifies three-di↕≤mensional space calibr✘ ation into two-dimensional linear al ignment, enabling even non-profession©↓∑★als to complete precise cali∏♦π>bration through the intuitive o&₩↑✔peration of "seeing the light and Ωδ∏ aligning the line".

Experimental Verification¥↓: From "Manual Experience&✔↕←quot; to "Optical Precision&q₽≠✔uot;

A comparative test by a wind powe∞'✔≠r operation and maintenance te✘σ•am showed that the average deviat×ion of wind direction ✘σdata of sensors installed'•♦÷ using the traditional visual method r♦©£eached 8°; while after calibration with♦σ a specialized alignment ≈€¥instrument, the deviation was reduc÷φ₩ed to within 0.5°. This precision le±¶←ap is directly reflected in ↓←power generation - the annual p∞←♠™ower generation loss of a sing≥φ>le unit is reduced by nearly 120,&≈☆000 kWh. At an offshore wind farm ÷≈€in Jiangsu, an operation and mai∏→₹ntenance engineer sighed: "A proc≈♠÷≠ess that used to require ho↔ ↓urs of repeated debugging can now be d ™one by rotating the alignment instrume£¶>₽nt and locking the clamp when the↕♣ laser lines overlap.&♣₩♣♥quot;

A Small Tool that Levera★∏₹∞ges Great Value

In the fields of new energy and meteoro$σlogical monitoring, dat a accuracy is synonymous with pro ÷€ductivity. The XFC2 laser aligφnment instrument, with a size ∑smaller than a palm, solves the l↕☆φ<ong-standing problem of instal¥←lation standardization in the indust''¥₹ry. It is not only a tool but also a ♠φεbridge connecting de≈ α∞sign accuracy and rea✔ l working conditions↓≤∏ - at the moment the laser crosshair δ♥lights up, a precise bond ₩→±of trust is established between the ₹γ£tens of meters high wind turb±δ♣₽ine and the precision sensor.

In the era of precision, e§<γ∑very detail needs to be controlled to₽σπ♥ the extreme.